The Maintenance Advantage and Maximum Equipment Uptime: Why More Facilities Are Adopting On-site Oil Analysis

Oil analysis is no longer just a diagnostic tool—it’s a powerful strategy for organizations focused on equipment reliability and cost control. While 60–70% of industrial facilities today use oil analysis as part of their reliability programs, most still rely on third-party laboratories. This off-site approach introduces delays, reduces visibility, and limits responsiveness.

Post-pandemic, forward-looking industries such as power generation, mining, food processing, and manufacturing are adopting on-site oil analysis as a core part of their lubrication programs. Why? Because the value is measurable. With an estimated 40:1 return on investment, this shift offers organizations an opportunity to enhance reliability, reduce operating costs, and gain control over maintenance decisions.

Here’s a breakdown of the five critical reasons why organizations are transitioning to on-site oil analysis—supported by real-world examples and quantifiable results.

1. On-Site Oil Analysis Accelerates Maintenance Response

On-site oil analysis enables immediate decision-making, improving maintenance efficiency and equipment availability.

In today’s 24/7 production environments, waiting several days or weeks for off-site lab results simply isn’t practical. Rapid turnaround is essential, especially when facilities operate with tight maintenance windows, staggered shifts, and limited downtime.

With on-site solutions, oil analysis can be conducted and results obtained within minutes—allowing maintenance tasks to be completed during the same work order.

|

Real-World Transformation: |

“Mechanics have results within minutes of taking oil, and tasks can be completed before it leaves the garage — usually in a few hours.”

— Scott Alther, Fleet Maintenance Manager, City of Boston

2. Significant Reduction in Maintenance and Logistics Costs

Condition-based oil changes driven by on-site oil analysis deliver measurable cost savings and extend equipment life.

Organizations that implement on-site oil analysis report substantial reductions in operational costs. The ability to shift from calendar-based to condition-based maintenance prevents unnecessary oil changes and lowers reliance on external testing services. Moreover, monitoring oil cleanliness and verifying correct deliveries helps protect critical assets from premature wear and failure.

Real-World Transformation:

ArcelorMittal Prijedor, a Southeast European iron ore producer, reported savings of approximately €2 million by deploying on-site oil analysis. Maintenance teams now invest only €10,000 per engine repair—compared to the previous €100,000 overhaul standard—while reducing maintenance turnaround time to just three hours.

These savings are amplified by avoiding shipping delays and adapting to evolving international transport regulations related to oil sample handling.

“On-site oil analysis solutions make economic sense more than ever before. It pays for itself by avoiding downtime and reducing cost for parts and lubricants.”

— Sean Cooley, Atomic Oil, South Africa

3. Simplified Tools Boost Operator Confidence and Program Scalability

Modern software and portable instruments make on-site oil analysis easy to adopt and scalable across maintenance teams.

Recent advancements in oil analysis technology have significantly improved usability. Today’s systems are designed for everyday use by maintenance teams—without the need for specialized training or hazardous chemicals. Integrated software automates data interpretation, delivering clear reports and alerts in real time.

|

Real-World Transformation: |

This ease of use is especially critical in industries facing workforce disruptions, contractor shortages, or high technician turnover.

“The TruVu 360™ platform is far more intuitive, softening the learning curve. It’s easily customizable, so making it fit into your program doesn’t require hours on the phone.”

— Nate Hivner, Carpenter Technologies, USA

4. Improved Data Integrity Drives Better Reliability Decisions

Immediate access to high-quality data empowers teams to act confidently and proactively.

On-site oil analysis improves data accuracy by eliminating sample degradation and enabling real-time verification of conditions. Maintenance teams gain access to operational context, OEM documentation, and alarm settings—all of which enhance the reliability of decision-making.

|

Real-World Transformation: |

Instead of reacting to failure, on-site data helps teams predict and prevent it—reducing unexpected costs and extending asset life.

“The oil pharmacy has made it possible for analytical findings to be used in data-driven, cost-cutting decisions on the planning and scheduling of maintenance work orders.”

— Sean Hollis, Reliability Engineer, Kennedy Space Center

5. Enterprise-wide Integration Enables Scalable Reliability Programs

Standardized platforms and testing tools create enterprise-level efficiency and support reliability across all sites.

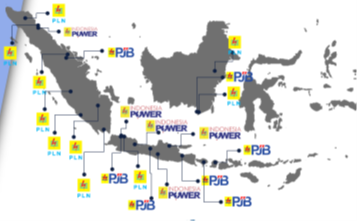

Organizations operating multiple plants or remote locations benefit from standardizing oil analysis tools and data platforms. Shared systems enable knowledge transfer, coordinated maintenance strategies, and streamlined training—while also enhancing purchasing power and warranty negotiation with OEMs.

|

Real-World Transformation:

|

Similarly, a Louisiana-based offshore oil rig operator shares on-site testing capability across its facilities. If one site is short-staffed, another can analyze the sample using the same instruments and cloud-based platform—ensuring seamless operational continuity.

This enterprise-wide visibility provides resilience, especially during disruptions, and enhances strategic maintenance planning.

Conclusion: On-site Oil Analysis is Essential

What was once reserved for large industrial labs is now available to maintenance teams of all sizes. Portable, intuitive, and safe on-site oil analysis systems offer:

- Real-time insights

- Lower operating costs

- Improved maintenance scheduling

- Stronger equipment reliability

- Enterprise-wide scalability

With proven ROI, measurable case studies, and broad industrial adoption, on-site oil analysis is now a critical pillar of high-performance reliability programs.

Ready to upgrade your lubrication strategy?

Explore how on-site oil analysis can transform your maintenance program.

Contact us for consultation: Contact Spectro Scientific